New Battery Tech Generates Power and Purifies Water

Scientists in India have developed new battery tech that produces electricity and cleans wastewater at the same time.

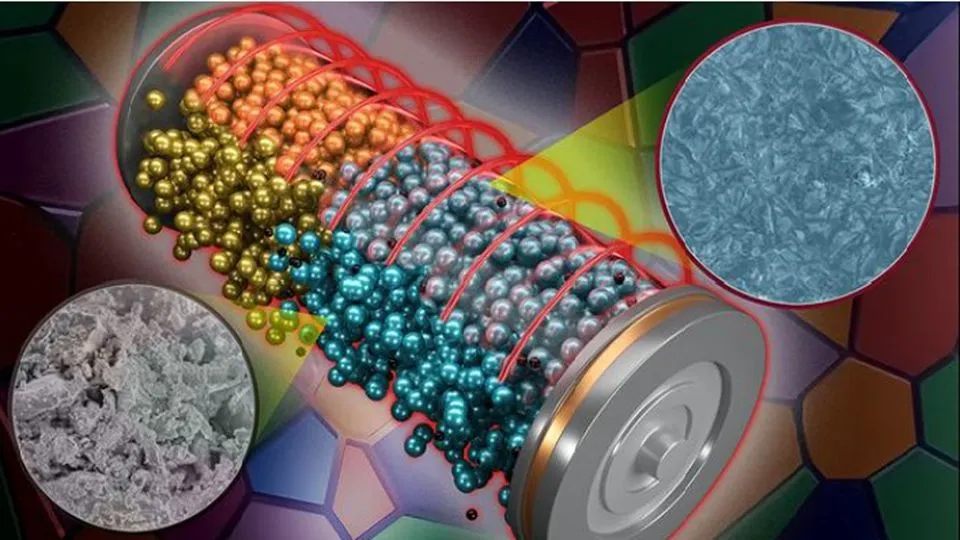

Researchers in India have unveiled new battery tech that can do two things at once: generate electricity and purify wastewater. A revolutionary approach to the standard zinc-air battery combines electricity generation with water cleaning operations. The special electrocatalyst in hybrid technology enables both power generation and pollutant breakdown including ammonia and urea from industrial wastewater.

The solution combines two processes in one tiny unit unlike standard energy and water filtration methods that operate in different dedicated spaces. The implications for developing regions, off-grid communities, and sustainable industries are profound, making this new battery tech a potential game-changer.

How the Technology Works

At the core of this new battery tech is a novel catalyst, a cobalt-nickel-iron alloy embedded in nitrogen-doped carbon. The system enables waste management through nitrogen waste elimination procedures while it produces electrical power. In this special configuration the battery functions autonomously using water contaminants instead of external power or fresh water through chemical operation.

The testing confirmed that the battery supplied reliable power for more than 180 hours and removed 94.5% of nitrogen waste during this period. A performance level reaching 94.5% efficiency makes the barrier system a practical substitute to other resource-consuming water treatment systems while generating useful electric energy.

A Sustainable Answer for Industrial Pollution

Urea-rich waste disposal proves challenging for industries working in agriculture or manufacturing sectors. The new battery tech not only handles these pollutants efficiently but converts them into harmless nitrogen gas through a process called electrocatalytic oxidation. The electrocatalytic oxidation process consumes minimal energy and avoids harmful waste generation during urea waste treatment.

When it comes to energy capabilities the battery matches its performance to standard zinc-air batteries because of its voltage strength and current delivery ability. This means that facilities adopting this new battery tech won’t have to sacrifice energy performance to gain water treatment capabilities. The power efficiency from this discovery makes it useful both as a power supply for low-energy equipment and emergency backup for off-grid systems according to researchers.

Final Thought

The next step for this new battery tech involves scaling up production and testing in real-world industrial environments. Researchers plan to improve the catalyst to generate even higher productivity levels while they build commercial relationships to bring products to market. This dual-purpose battery shows promise for integration into eco-friendly factory installations and rural healthcare facilities as well as emergency shelters because of growing sustainable infrastructure interest.

If commercialized effectively, this new battery tech could mark a turning point in how we approach environmental engineering. Future operations will combine energy systems with sanitation facilities using cheaper integrated solutions that provide green and scalable results. Communities together with industries may achieve their future clean energy needs and water sustainability through a unified revolutionary solution.